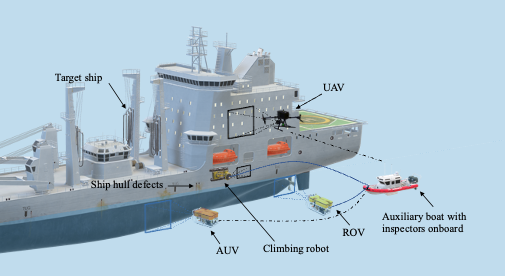

The diagram of the inspection of a ship hull using robots, including the Automated Underwater Vehicle (AUV), Remotely Operate Vehicle (ROV), Unmanned Aerial Vehicle (UAV) and climbing robot.

Abstract

To ensure the safety of ship navigation, a regular hull inspection is essential, which can identify affected structures and guide the appropriate maintenance.

Traditional hull inspections severely rely on inspectors who tour the entire hull and perform close inspections, which are tedious, subjective, dangerous and

expensive. The applications of computer algorithms and robots to data processing and data collection respectively have been receiving increasing attention, to

facilitate hull inspections and reduce costs. In this paper, we first review the background knowledge of hull inspection. Then we categorize different inspection

approaches into three classes: in-dock, underwater and health monitoring based inspections and conduct an extensive, deep survey. In addition to manual inspection

approaches, we survey both the automatic data processing methods and automated platforms used to improve the efficiency and effectiveness of hull inspection. Different

approaches are reviewed based on the type of Non-destructive Testing (NDT) techniques, data processing methods and automated platforms. Discussions are further made

regarding the existing work. To our knowledge, this study is the first survey performed in such an extensive manner, which can help both the research and industry colleagues

build up an overall understanding of hull inspection and identify potential directions for future development.

Background knowledge of ship hull inspection

In this section, we will briefly review the background knowledge involved in hull inspection, including different hull defects, NDT techniques and automated robots...

In-dock ship hull inspection

In-dock ship hull inspection aims to ensure the structural condition of a ship meets the requirements of seaworthiness. Special survey and bottom survey are two forms

of in-dock ship inspection methods defined by the IACS. They are normally carried out every five years in dock (IACS, 2007). To be specific, the special survey is normally

used to perform a close-up assessment associated with thickness measurement and can be used to detect bucking, corrosion, fractures and other structural...

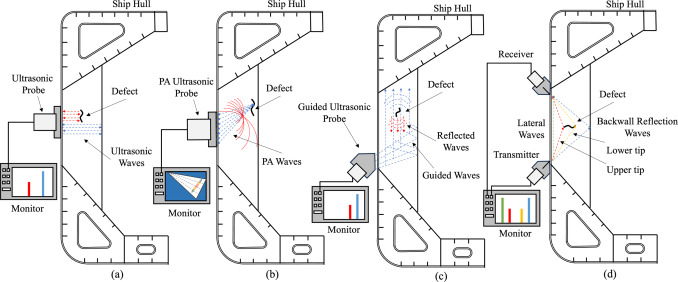

The principles of applying three different ultrasonic testing techniques to a ship hull structure, including (a) Pulse-echo Ultrasonic Testing, (b) Phased Array

Ultrasonic Testing and (c) Guided Wave Ultrasonic Testing. (d) Time-of-flight diffraction Ultrasonic Testing.

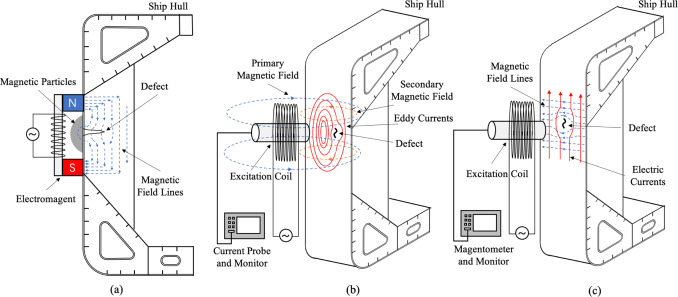

The principles of applying three different types of electromagnetic testing techniques to a ship hull structure, including (a) Magnetic Particle Inspection,

(b) Eddy Current Testing and (c) Alternating Current Field Measurement.

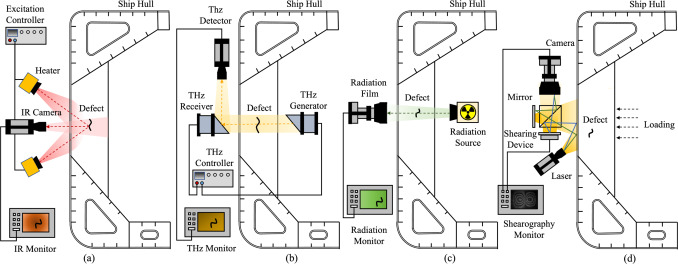

The principles of four sorts of imaging-based testing techniques applied to a ship hull structure, including (a) Infrared Thermography Testing, (b)

Terahertz Imaging Inspection, (c) Radiographic Inspection and (d) Laser Shearography Testing.

Underwater ship hull inspection

According to the requirement of IACS, an underwater inspection of the ship bottom can be performed with the ship afloat (IACS, 2019b). This type of ship inspection, referred

to as In-Water Survey or Underwater Inspection in Lieu of Dry-Docking (UWILD) Survey, can be used to acquire the data which is usually derived using a docking survey. Compared

with in-dock inspection in which the ship has to be taken out of service and enter a dry dock, UWILD can be fulfilled in the case that the ship is...

Health monitoring based ship hull inspection

Structural Health Monitoring (SHM) systems have become a recent development in the damage detection of ship hulls. To archive the structural response when a ship is normally operated,

these systems utilize different sorts of accelerometers, sensors and strain gauges (Frangopol and Soliman, 2013, Beko et al., 2021).

Different tasks can be fulfilled using the SHM systems, including damage detection, damage diagnosis, damage prognosis, monitoring the structural response in normal operations,...

Discussion

Ship hull inspection is necessary for safe navigation because it enables the proper functioning of a vessel. Therefore, the inspection operation needs to be carried out on a regular basis.

Traditionally, hull inspection is manually conducted in-dock using visual testing, ultrasonic thickness measurement, ultrasonic testing, electromagnetic testing, etc. However, in-dock inspection

is time-consuming and economically unproductive, because the vessel has to be out of service, arrive at the...

Conclusion

In this paper, we reviewed a large number of publications related to ship hull inspection. Particularly, we focused on the different NDT techniques involved in many inspection tasks. In terms

of these techniques, we investigated a series of manual inspection approaches and the automatic data processing methods and automated platforms used for automated inspection.

To be specific, we first reviewed the background knowledge of hull inspection, including different types of hull defects, various...